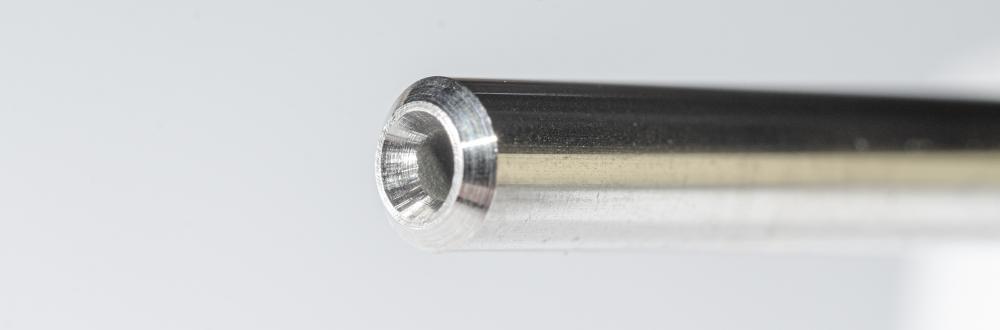

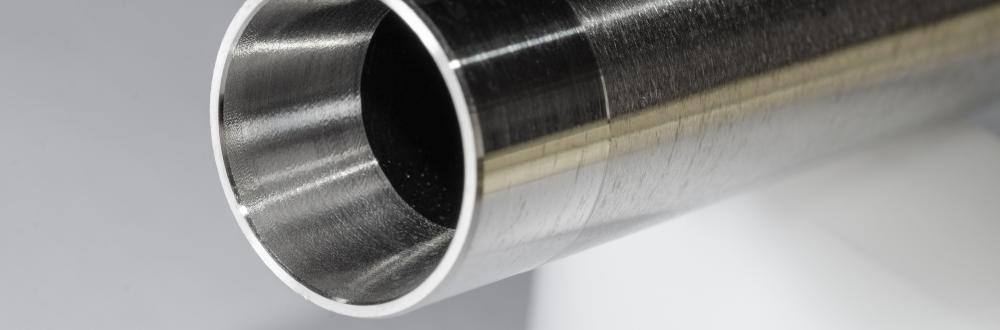

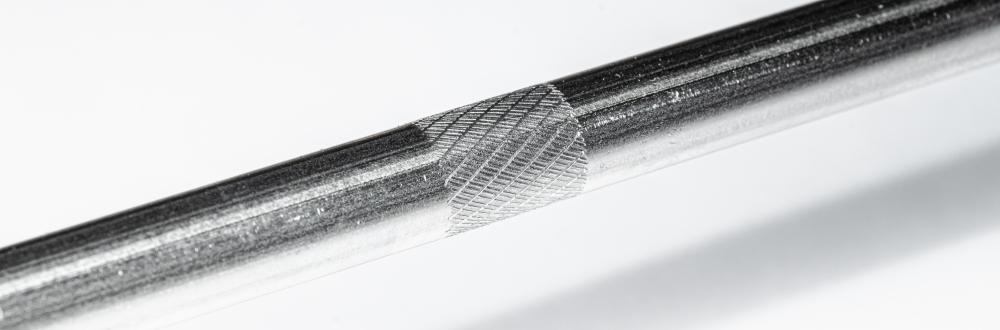

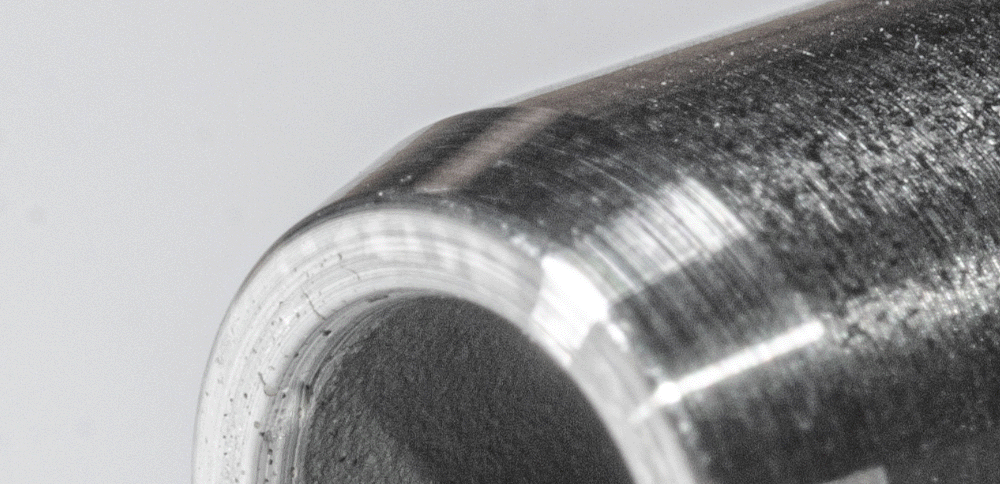

Chamfering

Chamfering is one of the most precise and cleanest deburring processes. The workpiece is machined on both sides using defined tools. In the process, a defined geometry is applied to the respective tube ends. This geometry can be designed as an angle or a radius.

Chamfering can increase the durability of the tools due to the accuracy of fit of the workpieces in further processing. In addition, very narrow length tolerances are possible.

Let’s chamfer it.

| Outer diameter | 4,0 – 105,0 mm |

| Wall thickness | 0,4 bis Vollmaterial |

| Length | 16,0 – 2.000,0 mm |

| Length tolerance | ± 0,1 mm |

| Special tolerance | < ± 0,1 mm ( auf Anfrage) |

| Material | Steel, stainless steel, copper, aluminium |